In recent years, legislative and market

requirements have driven the need to reduce fuel consumption while meeting

increasingly stringent exhaust emissions. This trend has dictated increasing

complexity in automotive engines and new approaches to engine design. A key

research objective for the automotive engineering community has been the

potential combination of gasoline-engine specific power with diesel-like engine

efficiency in a cost-competitive, production-feasible power train.

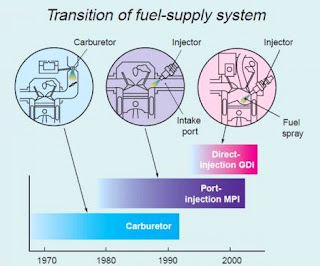

One promising engine development route for achieving these goals is the potential application of lean burn direct injection (DI) for gasoline engines. In carburetors the fuel is sucked due to the pressure difference caused by the incoming air. This will affect the functioning of the carburetor when density changes in air are appreciable. There was a brief period of electronically controlled carburetor, but it was abandoned due to its complex nature. On the other hand in fuel injection the fuel is injected into the air.

Advantages

1 Frequent

operation in stratified mode.

2 Reduction

of CO2 production by nearly 20 percent.

3 Provides

improved torque.

4 Fulfills

future emissions requirements.

5 97%

NOx reduction is achieved.

6 Improve

the brake specific fuel consumption.

7 Smooth

transition between operation modes.

0 comments: